Vacuum homogenization emulsifying machine

Application

ApplicationThis equipment is mainly used for high viscosity emulsion, in particular cream, ointment, emulsion products manufacturing

Working principle

Working principleThe materials are heated and mixed in the water pot and the water pot, then it was pump to the emulsion pot by the vacuum pump. In the emulsion pot , there is a scraper which whirls with high speed to shear the materials. Next, the materials flow to the homongenizer and finally realize vacuum suction.

Introduction

Introduction

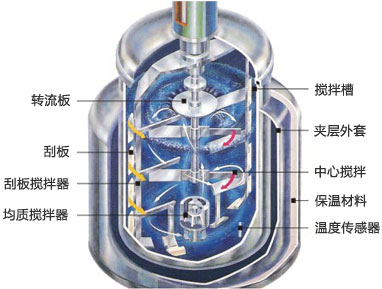

Structure

The machine is composed of emulsion pot (which can lift the lid, with flip-type pot body) water pot, the pan, vacuum devices, heating and temperature control system, cooling system, electrical control system, etc.

Features:

- The matrerial pot is auotomatic lifting. The materilas are sucked to emulsion pot by pipeline in the water pot and the oil

- cooling system is installed, it's easy control, convenient for operation, theat preservation

- Small fineness, time saving, high effect in mixing, dispersing,homongenizing, and emulsion.

- The parts contact with materials are made of SS 304\SS 316. Both side are miror polished

- The homogenizing mixing and paddle mixing can be used independently.

- It adapts heating conduct pipe to heat.

| YT-VACUUM HOMONGENIZER | YT-10 | YT-30 | YT-50 | YT-100 | YT-150 | YT-200 | YT-200 | YT-300 | YT-500 | |

| EMULSION POT | DESIGN VOL (L) | 10 | 30 | 50 | 100 | 150 | 200 | 200 | 300 | 500 |

| CAPACITY (L) | 8 | 25 | 40 | 80 | 120 | 120 | 160 | 240 | 400 | |

| SCRAPER POER (KW) | 0.18 | 0.75 | 0.75 | 1.1 | 1.1 | 1.5 | 1.5 | 1.5 | 2.2 | |

| SCRAPER SPEED (RPM) | 10.120 | |||||||||

| HOMONGENIZER POER (KW) | 0.55 | 1.5 | 1.5 | 2.2 | 3 | 4 | 7.5 | 11 | - | |

| HOMONGENIZER SPEED | 2800 | |||||||||

| WATER POT | DESIGN VOL (L) | 5 | 20 | 35 | 60 | 90 | 120 | 180 | 300 | - |

|

CAPCITY (L) |

4 | 16 | 28 | 50 | 75 | 100 | 150 | 250 | - | |

| MIXING POWER (KW) | 0.018 | 0.18 | 0.18 | 0.55 | 0.55 | 0.75 | 0.75 | 1.1 | - | |

| MIXING SPEED (RPM) | 80 | 60·1000 | ||||||||

| OIL POT | DESIGN VOL (L) | 5 | 15 | 25 | 40 | 60 | 80 | 120 | 200 | - |

|

CAPCITY (L) |

4 | 12 | 20 | 35 | 50 | 65 | 100 | 165 | - | |

| MIXING POWER (KW) | 0.018 | 0.37 | 0.37 | 0.55 | 0.55 | 0.75 | 0.75 | 1.1 | - | |

| MIXING SPEED (RPM) | 80 | |||||||||

| VACUUM | MOTOR POWER (KW) | 0.12 | - | - | - | 0.55 | 2.2 | 1.1 | 1.5 | 1.5 |

| VACUUM (MPA) | -0.09 | |||||||||

| LIFTING SYSTEM | MOTOR POWER (KW) | - | - | - | 0.75 | 1.1 | 1.1 | 2.2 | 2.2 | |

| LIFTING SYSTEM | MANUAL | ELECTRONIC | HYDRAULIC | |||||||

Notice

NoticeIt is costomizable. But please kindly send us the specific demand when you make a enquiry. Thanks for your understanding!

Inquiry:(If immediate response needed, please call (86-28-62812181) or send e-mail to kf@yonton.com)